How we fit

MOPS is a Manufacturing Information Warehouse (MIW) that has specialized applications for automating production loss time reporting, analyzing paper and bale quality information, evaluating and reporting quality production statistics, and tracking machine equipment performance.

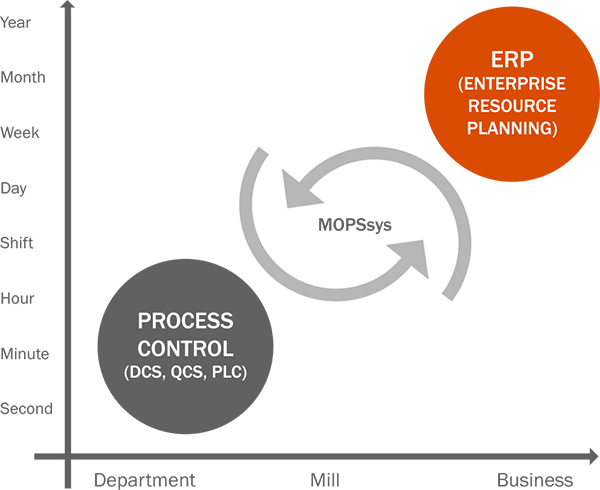

When you look at a typical pulp and paper operation, you’ll see that process control data is usually available on an hourly, minute and second basis. At the other end of the spectrum, business data for the financial systems is required on an annual, monthly, weekly and daily basis. MOPS positions itself right in the middle by providing consolidation, integration and distribution of this data with a product suite of applications that turns the data into useful information.

The multitude of data that a MOPS system can pull together comes from many different sources including distributed control systems (DCS), quality control systems (QCS), programmable logic controllers (PLC), supervisory computers, data processing systems, automated paper and pulp lab systems, maintenance systems, manufacturing execution systems (MES), enterprise resource planning (ERP) systems, and other process information management systems (PIMS).

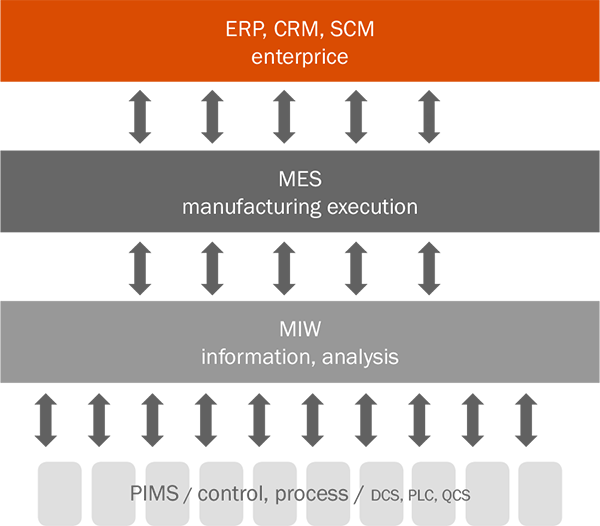

Manufacturing applications typically comprise of production management, planning and scheduling, product tracking, warehousing and shipping, quality management, process management, process information databases, and asset management.

These applications can be split in two categories: MIW – process and product area; and the traditional MES covering more of the production finishing line.

There is a logical split between these two layers:

The MIW layer focuses on the process and product side of papermaking, whereas MES focuses on order fulfillment. The dividing line is usually at the winder in the paper mill, as everything that happens prior to this point has an impact on the final quality.

MIW combines a process information database with a relational database and analytical processing tools. This data warehouse provides decision support to improve productivity, reduce losses and costs, improve quality, and meet environmental standards. Getting the necessary information is done by integration with the many different control systems, quality systems, environmental systems and production systems at the mill level.

The traditional MES layer captures information from the customer order and transforms it into a production order telling when and on what machine the customer rolls will be filled. From the winder, the jumbo reel is cut into the orders matching the customers’ product specifications. The product is then cut and converted and packaged according to the order, and moved through the finishing processes either directly to the loading dock or to the warehouse.

The coming together of the time-based real-time data (PIMS) with event-based relational data (MES, ERP) makes MOPS and its MIW an exceptional tool for analyzing, evaluating and troubleshooting between what’s happening on the operating floor and what’s happening with your business. Think of MOPS as being the Quality Manager for your mill and enterprise systems.